The corrosion of mooring systems for permanently moored offshore structures has long been a recognized challenge. This is particularly acute within the Oil & Gas industry, where corrosion of the chain is a leading cause of mooring failures and pre-emptive replacement of these systems in Floating Production, Storage and Offloading units. As floating offshore installations increase in number across other industries, this issue will present itself across the board, impacting the integrity of all systems.

Until today, the only solution to prolong the lifespan of these mooring chains has been to accept the corrosion with an ‘allowance’, using more steel and thicker chains. However, rates of corrosion can be unpredictable, varying hugely across the globe thanks to differing marine environments. At best, this results in significantly shorter than expected lifespans for the chains and at worst, increased failure rates and integrity issues in the mooring systems with costly, unplanned interventions to replace them.

Cathodic Protection has long been an integral part of the corrosion prevention strategies for offshore steel structures, but until now, this has not been successfully extended to protect the mooring lines themselves.

Setting a new standard in the protection of mooring systems

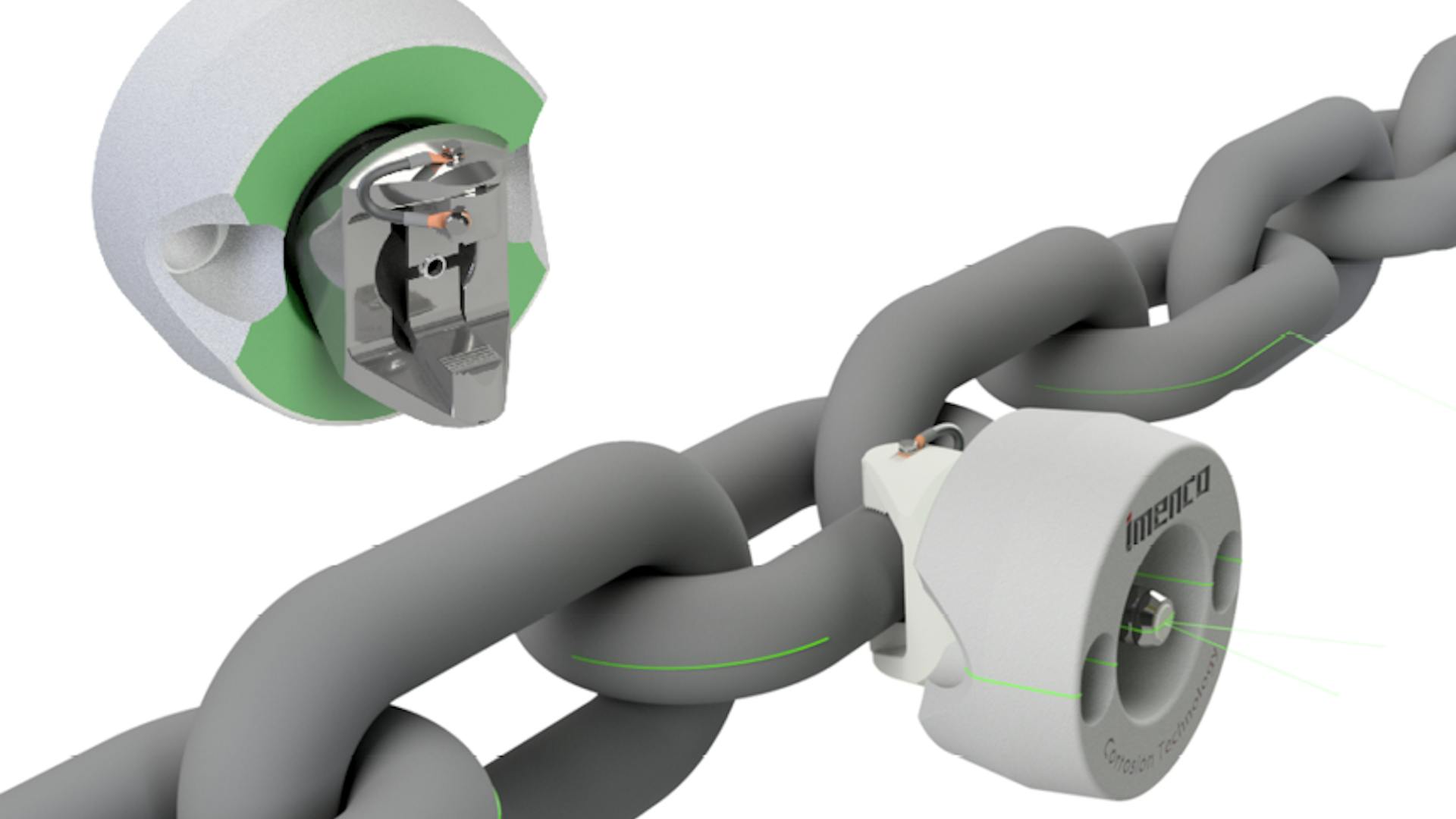

Capitalising on our extensive experience with Cathodic Protection, we at Imenco Corrosion Technology are setting a new standard in the protection of mooring systems. This now includes the chains on permanent offshore structures through the use of sacrificial anodes. Combining the incredible strength and conductivity of our industry-leading Piranha® clamp with a revolutionary system for the installation of anodes along the length of the chain, Pacu™ is transforming the available strategies for subsea chain protection.

Applicable to any permanently moored structure, the Pacu™ system is adapted to meet the needs of each installation. With the size, shape and spacing of the anodes engineered to fit the requirements of each mooring system, we ensure optimal corrosion protection no matter how challenging the environment.

Installed safely and efficiently using an ROV with our custom-built Tool Deployment Unit, the corrosion of chains is slowed dramatically. By avoiding the need for costly workovers and ultimately enabling companies to use thinner, lighter chains without compromising on their lifespan, Pacu™ helps to reduce the carbon footprint of chain management and supports the drive for greener, more sustainable operations.

Why Pacu™?

At Imenco, we pride ourselves in ensuring that every aspect of planning, installation and follow-up is thoroughly taken care of, so you can rest easy, knowing that your valuable equipment is fully protected.

Harnessing the leading expertise of our team within corrosion technology, we have developed a comprehensive combination of service and hardware to offer unrivalled protection from the corrosion of mooring chains.

Pacu™ provides a comprehensive corrosion-management solution and comprises of the following:

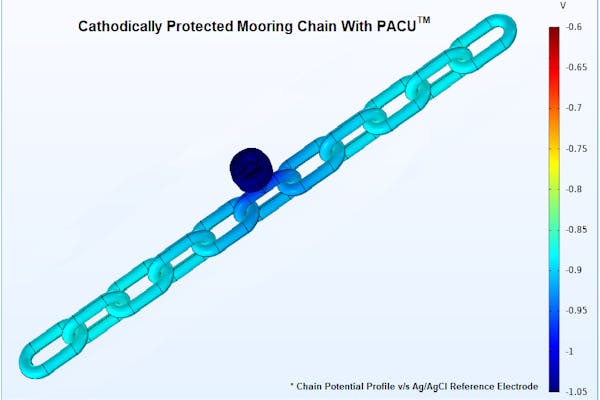

Modelling and engineering capabilities

- The expert knowledge of our team, combined with FEM/BEM computer simulation enables us to design a specific retrofit programme for any given field, defining number, size and locations for the optimal placement of the anodes

High quality, field-proven materials

- Imenco’s leading Piranha® clamp bites into the steel of chains, even though corroded surfaces, providing excellent

electrical connection - With its strong mechanical hold, is robust to dynamic motion and can withstand the loads exerted over the lifetime of the chain

Specially designed discrete sacrificial anodes

- Shape, size and spacing of anodes designed to ensure sufficient current is delivered to the chain to maintain protection in each campaign

- Anode composition is defined based on installation environment and/or client specification

- More anode mass with less support steel and reduced drag compared to anodes welded to support brackets

- Designed for easy collection and ROV installation using Imenco’s Tool Deployment Unit

Comprehensive installation process

- Our installation system has been designed for an efficient and safe installation campaign

- Our supervisory personnel are on-hand for installation campaigns, ensuring our unique installation methodology is successful first time, every time

Confirmation of protection

- Documentation to demonstrate sufficiently low resistance between chain elements to ensure chain protection

Validated system

- Effectiveness has been validated through extensive testing and a Technology Qualification Program with a major international operator

- Solution is in accordance with existing industry standards for general cathodic protection

Benefits:

- Extended lifetime and reduced risk of corrosion damage to mooring systems

- Lower likelihood of pre-emptive replacement of mooring systems

- Lower costs related to these unbudgeted replacements

- Can be easily retrofitted to any mooring system for immediate protection

- Reduced need for corrosion allowance will enable the use of thinner, lighter mooring systems in the future

- Reduce carbon footprint of operations thanks to fewer chain replacement campaigns and less steel

used in the chains themselves - Easy and safe installation process

Installation Process

- Safe, diver-less installation using ROVs

- Spacing and size of anodes required is assessed and modelled based on the particular environment of each installation

- Imenco’s Subsea Transportation and Storage unit allows up to 24 anodes and clamps to be pre-loaded at the

deck of the vessel for efficient deployment to installation depth - The anode interface is designed to ensure fast and easy collection by the installation tool

- This interface is also used to latch the anode/clamp assembly to the ROV’s custom-built Tool Deployment Unit (TDU) and to hold the anode/clamp assembly firmly in position until the ROV pilot releases the grip

- Line lasers, combined with the integrated camera in the TDU are used to assist the final approach to the chain to ensure alignment of both the unit and the clamp with the chain

This video is of a Pacu installation in Norway:

More details

The mooring system is protected by discrete anodes attached to our cornerstone product – our Piranha® clamp, mounted to a selection of chain links throughout the water column. Simple and robust in design, the Piranha® clamp is large enough to clamp effectively on to typical FPSO mooring chain dimensions, with excellent mechanical grip and well-documented electrical conductivity, even on heavily corroded or painted surfaces.

Downloads

Product Flyer - Pacu™

Contact