Corrosion control is an essential element of asset integrity strategies for all offshore structures. This is valid for both its initial stages and throughout its planned life span. For field life extension projects this becomes essential.

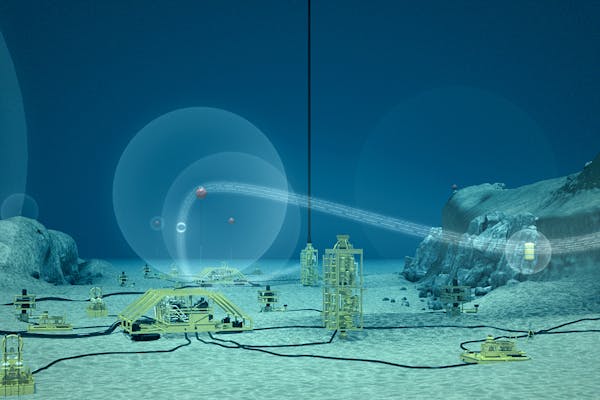

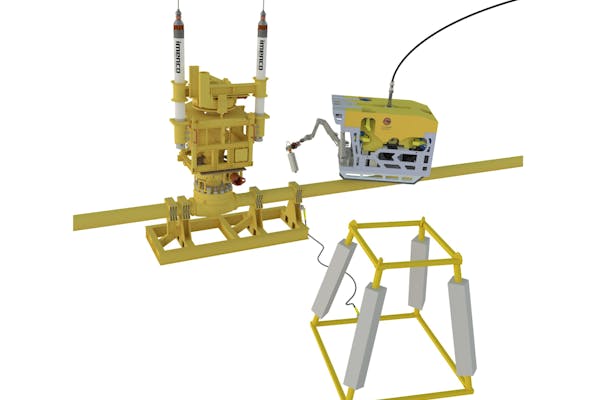

Imenco Corrosion Technology provides solutions, services, and products for corrosion monitoring and corrosion protection. Our company’s roots are in subsea engineering. Our core competences and products were initially ROV installable solutions for retrofit installation of cathodic protection. From these roots, we have developed a wide range of cathodic protection methods and products for the Ocean Industries and mainly for Offshore Oil and Gas and Offshore Wind. We have developed standardized solutions and working methods for a wide range of retrofit situations. These solutions provide a cost effective, diver-less, and very reliable method for installation of cathodic protection without any need for welding on site.

We are flexible in our project execution and, depending on customer requirements, our scope of supply can range from complete EPC projects to delivery of single components.

Advanced underwater wireless communication and positioning systems.

Using the latest generation of signalling technology, NASNet employs a broadcast technique providing true multi-user, accurate and reliable positioning in all water depths with no acoustic interference, providing clients with accurate positioning and substantial cost savings.

Our other Subsea Underwater Positioning and Navigation systems make use of Long Baseling (LBL), Short Baseline (SBL), and Ultra Short Baseline (USBL)

Subsea data transfer and control of seabed assets is available in our NASCoM product range.

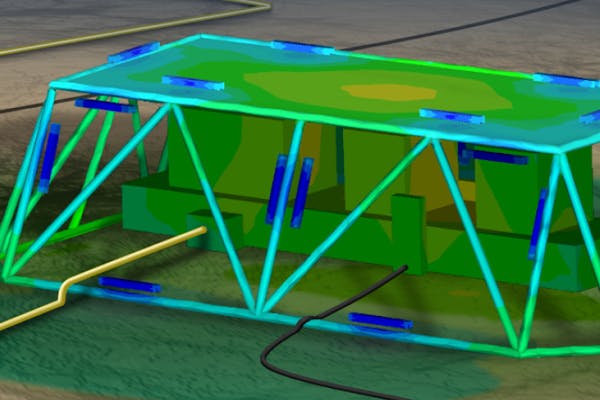

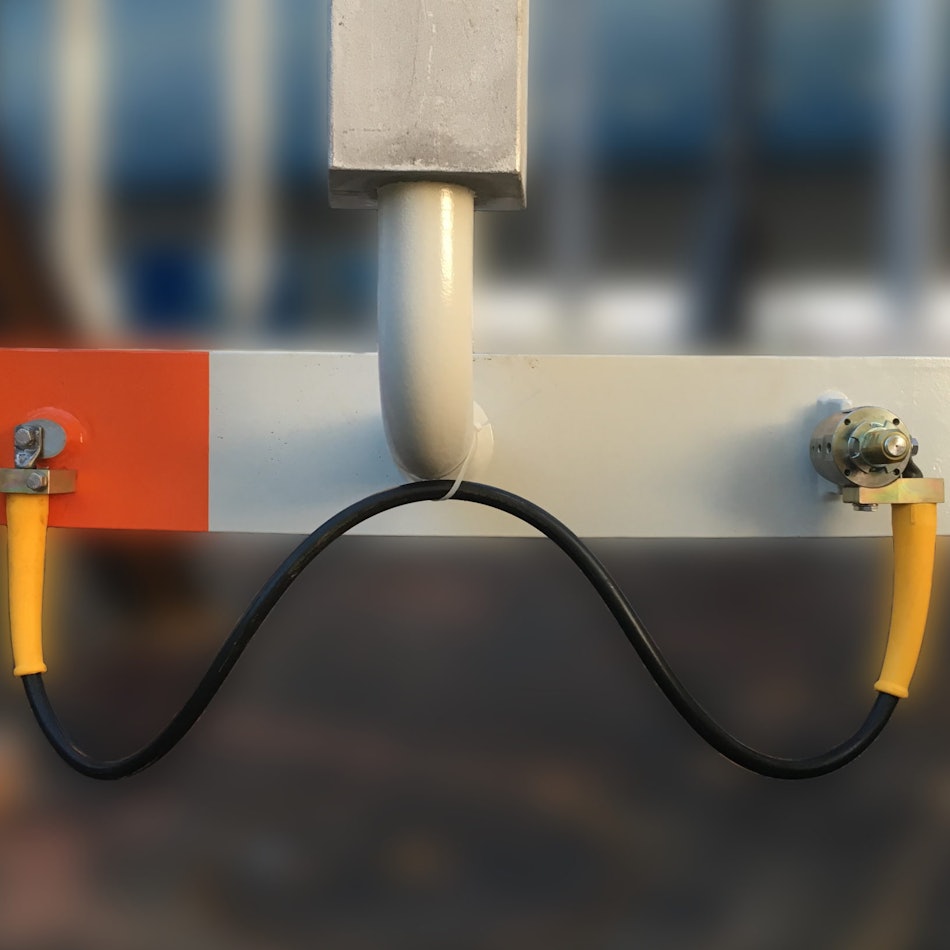

This section presents samples of how the Cathodic Protection System may be installed – primarily for retrofit projects.

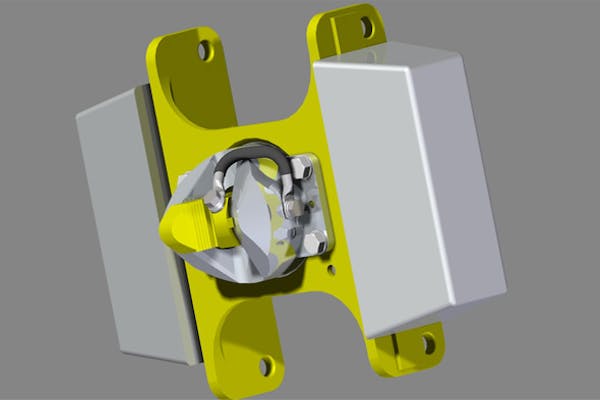

The anode will need a good electrical connection to the structure. Imenco have developed a wide range of well proven connectors for quick and easy subsea installation. If you have a structure – We can connect.

For any project we recommend that you discuss your project with our engineers as early in the process as possible. The earlier we come into the process – the better result we can achieve both in terms of quality and cost.

We have delivered cathodic protection solutions to clients in the offshore oil and gas for more than 15 years and to the fast growing offshore wind sector for 3 years. Even if most projects have elements that make them unique and therefor need some degree of individual engineering and planning individually, we can build on solutions developed for previous projects. We operate on a “modular philosophy” where the same standardized products and methods can be used for a wide range of applications. Some of those products and solutions are included as standard items in our toolbox – refined through years of experience. Through this standardization we can deliver products that are well documented, with short delivery times (often delivered from stock) and with the cost benefit that comes from repeated manufacturing. These products, methods and solutions are available and can easily be implemented as building blocks in a cathodic system design performed by us or by our clients.

We have presented some samples of previous project specific solutions as well as samples of standard products below. These examples cover Offshore Wind projects, Subsea Pipeline retrofit projects, solutions for cathodic retrofit of jacket structures and others.

Corrosion control is an essential element of asset integrity strategies for all offshore structures.

Get in touch with us or email us at imenco@imenco.com