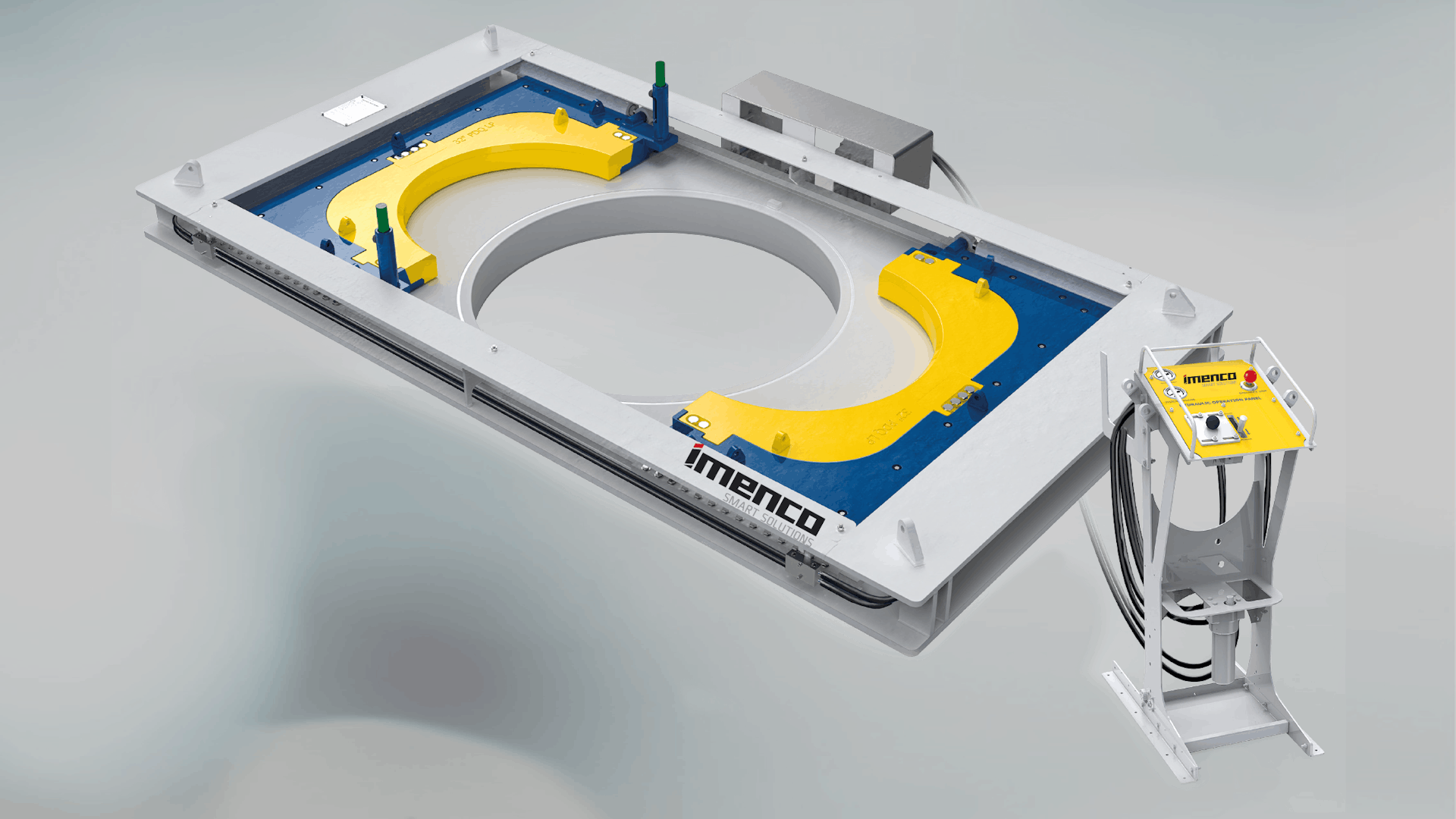

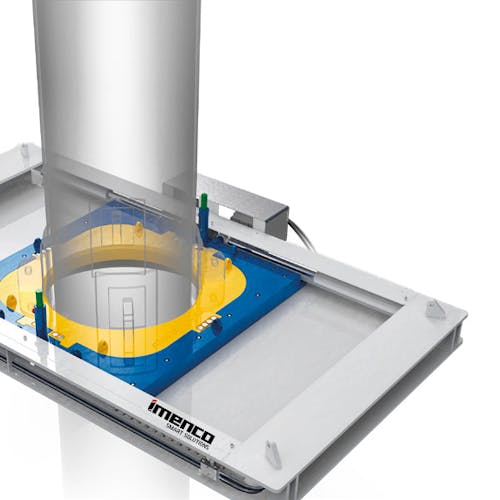

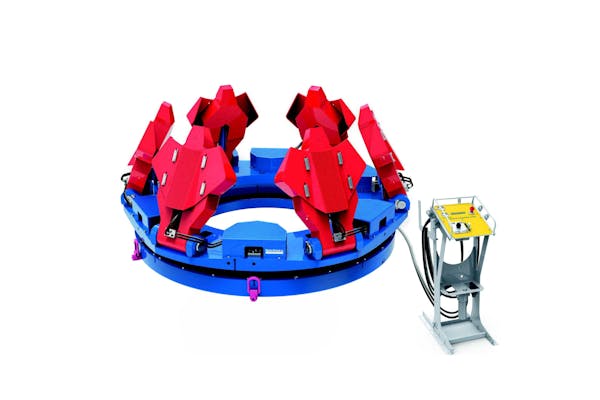

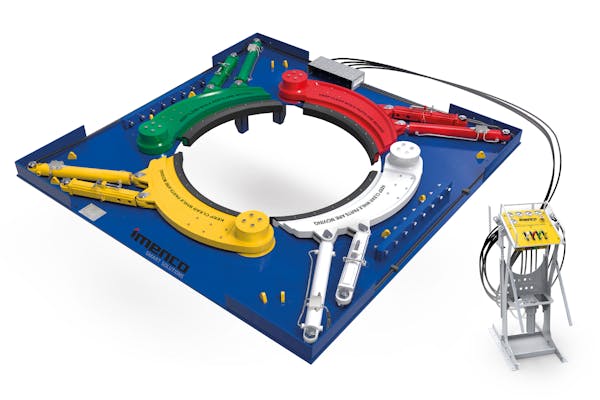

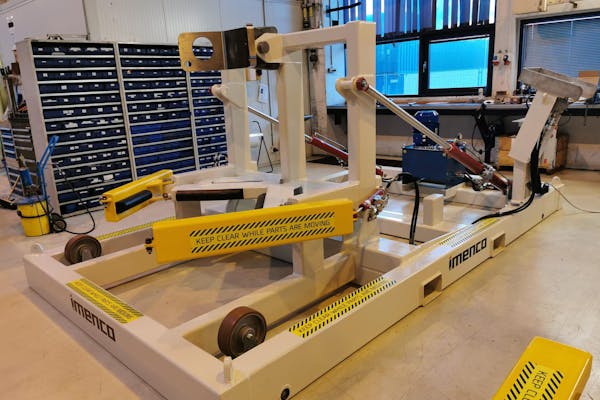

The hydraulic Riser Spider consists of a frame and sliding cassettes which slide along guide rails welded to the frame. The sliding cassettes include changeable inserts which are specific for each riser size. The Riser Spider can be locked in closed position by use of two manually operated mechanical locks. These locks will prevent spider to open even if unintended hydraulic activation occurs. System includes cover plate to avoid falling objects though the spider when not in operation.

More details

• Reduced production down time/Less Riser Handling time

• Safe operation with hydraulic or mechanical locking systems

• Easy to maintain and operate

• CE marked and EX approved

• Field proven

• HSE friendly as there are reduced need of operators close to the risers/ rotary table

• The Riser Spider is remotely operated by the control panel that allows the riser pushing or pulling operation to be controlled hands-free at a safe distance from the actual flange

• Control panel is connected to the Riser Spider through a quick connector panel that makes connecting/disconnecting more user friendly

• Operational temperature -200C to 600C

• Max operating pressure – System Approx. 150 bar

• Dimension: 3350x1800x430mm

• Riser range: 22,06’’, 22,76’’, 30,02’’ and 32’’

• Hydraulic fluid ISO vg32 as standard (other fluids applicable)

• EX zone approved Zone 2 (Zone 1 optional)

• 60T hang off load capacity

Contact