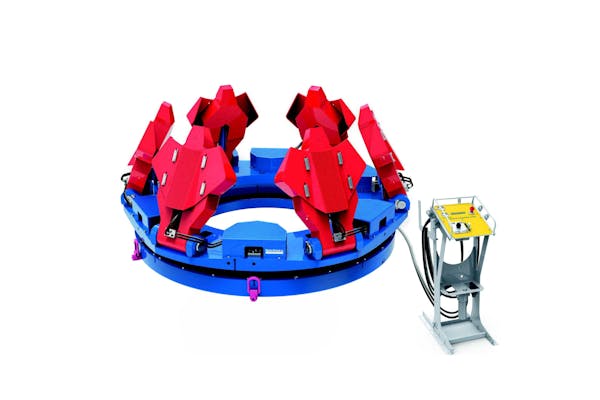

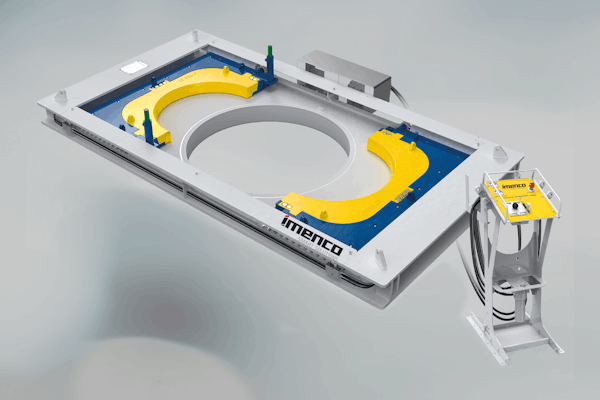

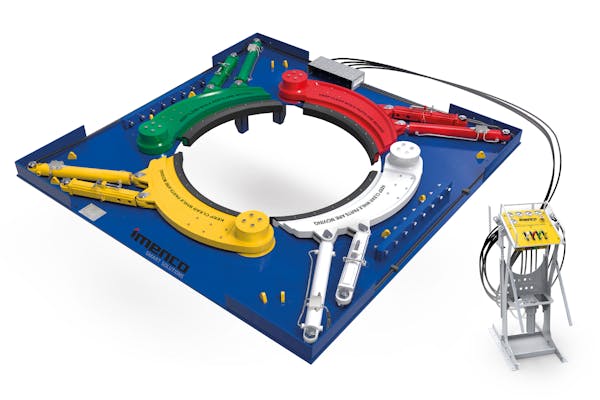

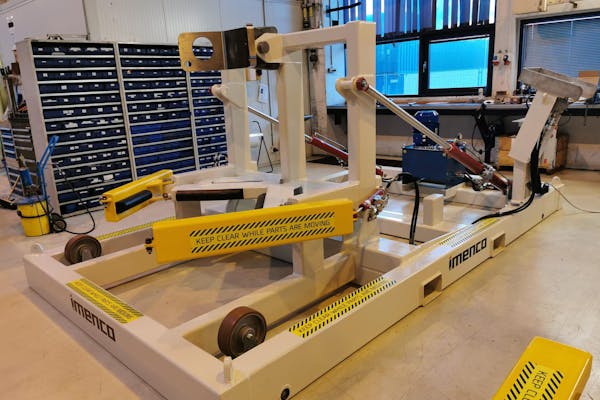

The Marine Riser Tension System is used on rigs and vessels to ensure constant tension for optimal riser stability. In recent years we have developed several types of wire tensioning systems.

It is crucial that the tensioner can manage differential movements between the riser and the rig as the riser is connected to the wellhead on the seabed. Without a tensioner the riser will buckle when the rig moves downward and stretch when the rig rises.

The use of hydro-pneumatic in a system comprising a hydraulic cylinder, accumulator and wire sheaves enables compensation for rig movements and maintains constant wire tension. We possess the design of several types of Marine Riser Tension System with different stroke lengths, power and interface, and we readily adapt these systems to individual customer needs.

More details

• The wire line tensioner cylinder utilities the hydro-pneumatic principle using cylinder with

dynamic seal elements at the cylinder gland and on the accumulator piston

• The riser tensioner can be arranged as single or dual units

• Adjustable tension force

• Imenco safety valve in case of wire damage

• DNV / ABS approval

• Anti recoil system and powered snubbing drum can be provided

• Customer adapted design possible

• Wire tension load: Up to 90 Tons (200 000 lbs)

• Wire stroke: 16 m (50 ft)

• Media: Nitrogen / Water Glycol

• Cylinder stroke: 4000 mm (12,5 ft)

• Imenco Safety Valve

• Max working pressure: 207 bar (3000 PSI)

Contact