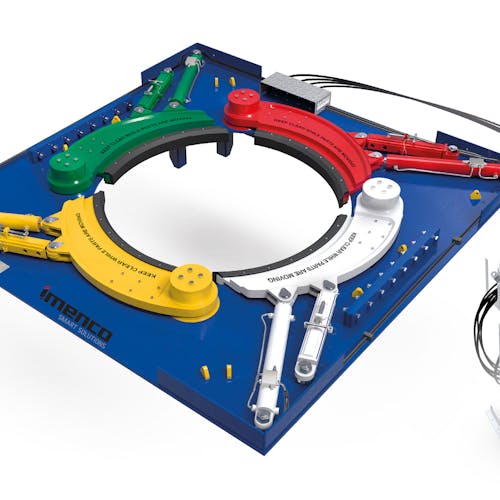

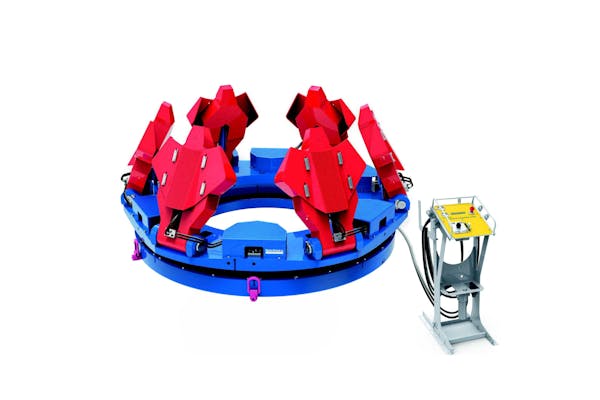

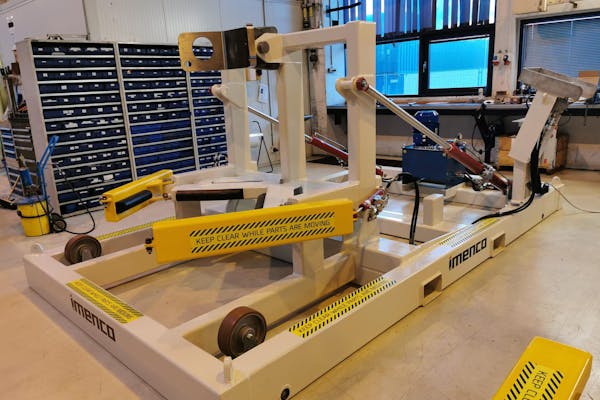

The Riser Centralizer consist of four independently controlled guide arms. The guide arms are able to pick up the riser wherever it is positioned in the hatch and centralize it. When operating the arms independently, their cylinders will push the guide arms out and centralize the riser.

The mechanical locking system is intended to hold the guide arms in position when the holding time is very long (~ 1 month). In this case the mechanical locking system will work as a security system preventing the guide arms to be pushed out of a specified position.

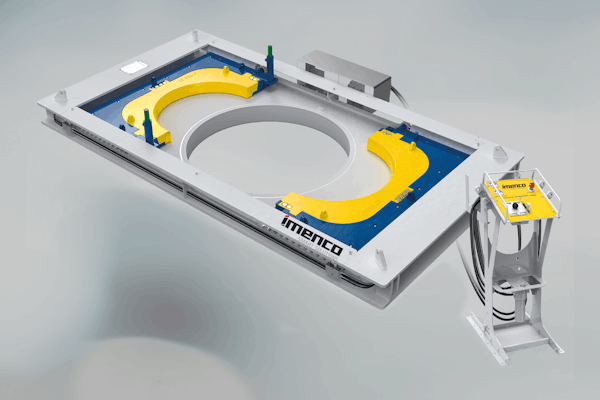

The Riser Centralizer also comes with a set of cover plates that shall be used when the Riser Centralizer isn`t operational and/or parked in a riser position for a period of time. These covers are there to reduce the risk of objects falling through the hatch.

More details

- Safe Operation with hydraulic or mechanical locking systems

- Easy to maintain and operate

- HSE friendly (4 different color on the guide arms makes the operation more visual)

- CE marked and EX approved

- The centralizer is remotely operated by the control panel. Each guide arm on the centralizer is operated independently

- Colors on each lever correspond with colors on the guide arms

- Control panel is connected to the Riser Centralizer through a quick connector panel which makes connecting/disconnecting more user friendly

- Field proven

- Operational temperature -200C to 700C

- Max operating pressure – System Approx. 160 bar

- Hydraulic fluid ISO vg32 as standard (other fluids applicable)

- Riser range: 22,06’’, 22,76’’, 30,02’’, 32’’ and 45,86’’

- EX zone approved Zone 2 (Zone 1 optional)

- Dimension: 3500x3500x550mm

- 93kN load capacity

Downloads

Product sheet - Riser Centralizer

Contact