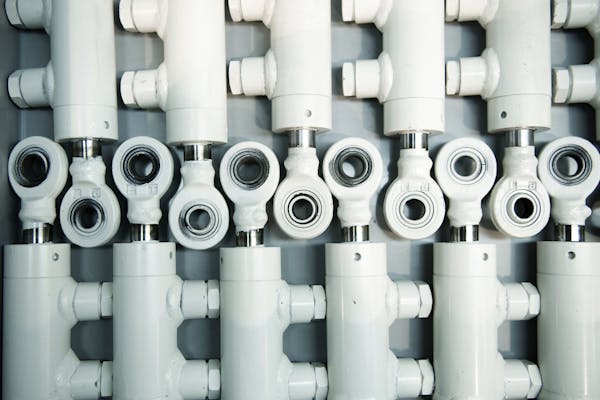

Hydraulic cylinders have for many years been our core product and we have built up a unique expertise in this type of product and service, both with our engineers and mechanics. With this expertise in hand, Imenco carries out daily repair and overhaul of all types and all sizes of hydraulic cylinders.

Defective parts that need to be replaced, such as pistons, stuffing boxes, piston rods, cylinder tubes, etc. are produced in our own machining department. We also have a honing bench available to repair internal damage in cylinder tubes. Piston rods and other worn or corroded parts can also be welded in our welding machine.

With flexible employees and good suppliers, we carry out this type of assignment in a minimum of time.

Typical process:

Dismantling and inspection to clarify the extent of damage.

Clarify improvements and price with customer.

Repair damage.

Assembly, pressure testing and painting.

Documentation according to agreement with the customer.

In some cases, there is a requirement for involvement from a third party, eg DNV. They will then be involved in the process listed above.

References:

Marine Riser Tensioner

Guide Line Tensioner

Crane cylinders

Cylinders for skid system

Cylinder for drill deck equipment (Catwalk, Roughneck, Riser Spiders, etc)

Cylinder for subsea equipment (Wellconnector, ROV Tool, etc)

Cylinder for excavators and trucks

Imenco is also helpful with disassembling and assembling equipment at the customer’s location.

Contact