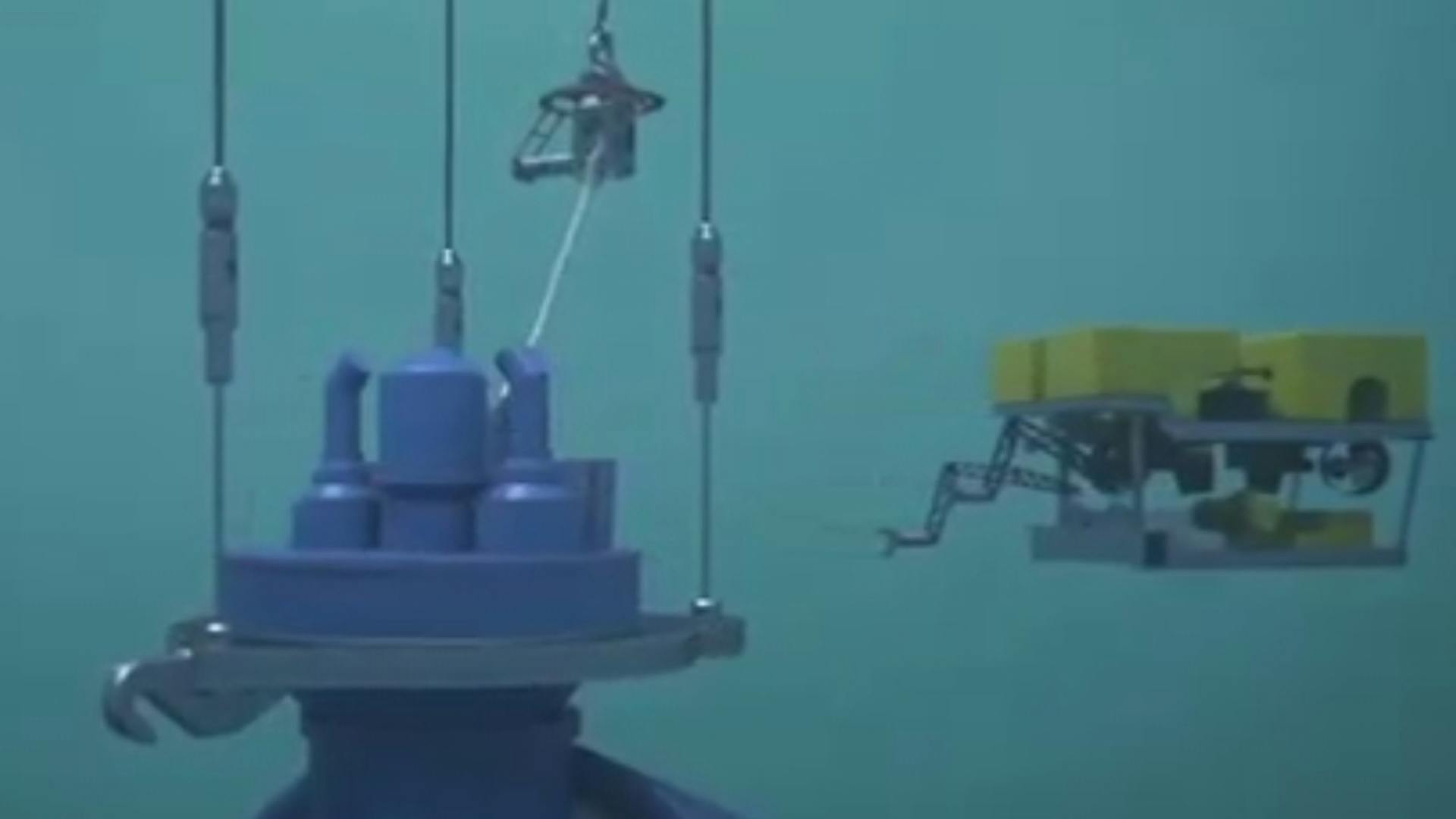

In 2014 a pre-study revealed challenges that deviated from the starboard side. The detail engineering was carried through in close cooperation with the customer, and after the best solutions was identified the manufacturing and FAT of an complex winch frame was finished. In addition to delivery of the winch frame, Imenco delivered the extension guide tubes and split-boxes in the thruster room, a new access hatch from main deck and 3 x custom made 25 Te lifting anchors for the thruster subsea lift.

Imenco planned and organized the work packs and supervised the modification works offshore – supplying welders, riggers, NDT operators and necessary equipment. Imenco supervised installation offshore and performed the mechanical completion so the system was ready for operation during spring of 2016.

Feedback from customer is entirely positive. “TRS (Thruster Replacement System) module behaved excellent, no vibrations or sign of weaknesses. Distance to surrounding structure were constant throughout the lift. Everything has gone incredibly well and we are extremely satisfied with what you have delivered”.