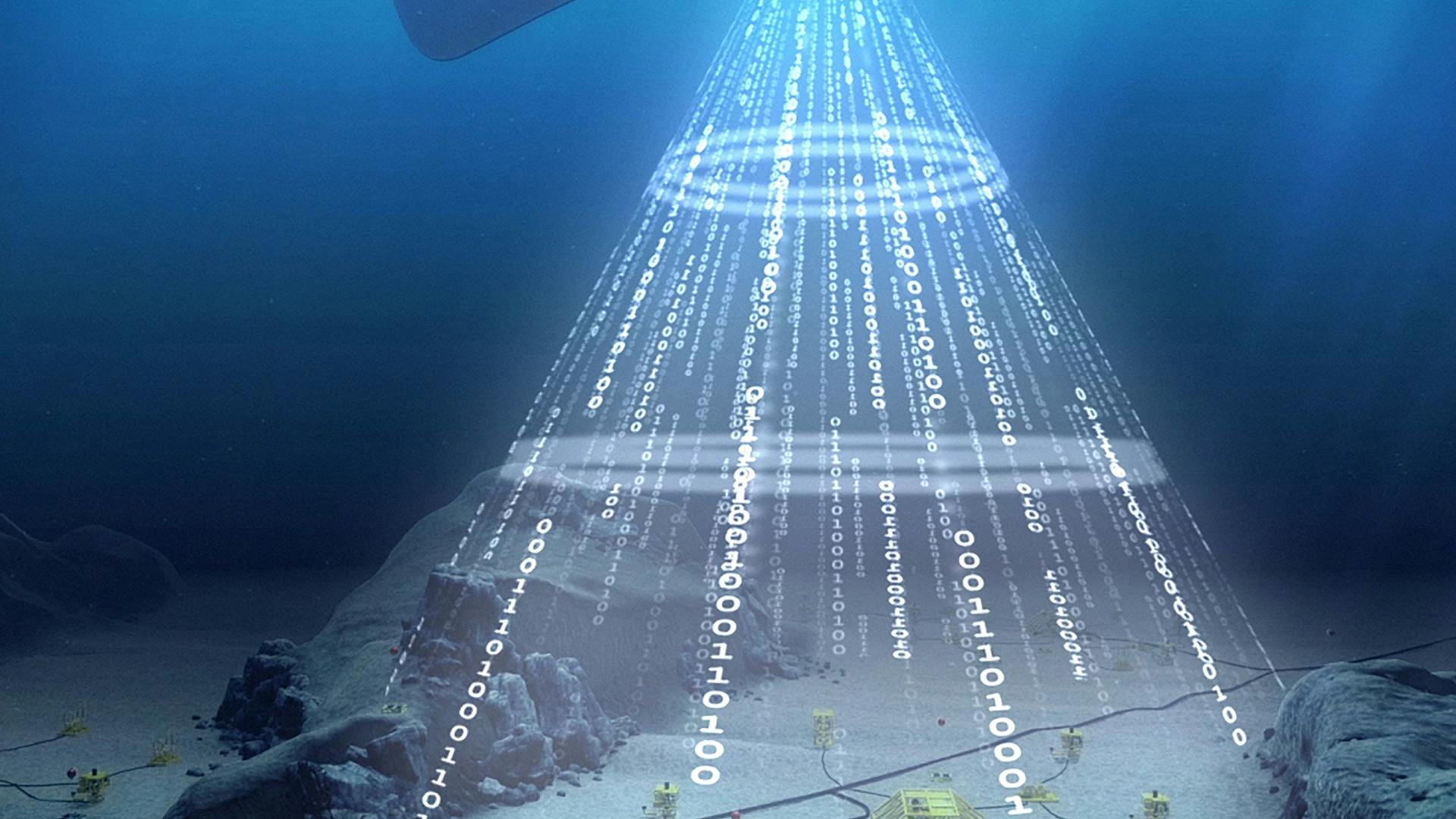

Subsea IoT

Imenco has combined expertise of acoustic communication and hydraulic systems to provide a turn-key, in-house offering of remotely operated hydraulic systems using long range wireless acoustic communication. With a continued move to an underwater Internet of Things, this is a key enabling technology for the field of the future.

Imenco Subsea Wireless Hydraulics Systems address a wide range of subsea applications such as subsea accumulator modules, chemical injection, mooring line releases, pipeline valves and manifold isolation valves.

This capability has become possible under the Imenco group where experts in these separate areas of technology have been able to share ideas between both sides of the North Sea and innovate using existing parts in the toolbox. The Imenco goal is to provide Smart Solutions to its customers, it was identified that wireless control of hydraulic systems can be a significantly less expensive option when compared to running downlines to subsea equipment or relying on an ROV intervention. The initial saving extends to long-term, avoiding the cost of maintaining long distance downlines.

The hydraulic system includes control valves, hydraulic supply via precharged accumulators or subsea HPU, custom panels for connection to hydraulic systems, and spent fluid capture avoiding venting of fluid to the environment. With wireless communication and a self-contained hydraulic system, this equipment can be deployed to operate functions without the need for electrical or hydraulic power run from surface or tied back to other control systems.

The robust acoustic communication technology has in excess of 25 years track record including acoustic emergency backup for acoustic BOP systems and primary control of subsea isolation devices. This critical functionality is the quickest controllable method of hydraulic valve operation should access to a primary control system fail and avoids the need to wait for ROV mobilization. This capability is only possible due to the highly robust digital acoustic signaling method and field proven hardware reliability.

Imenco in Norway has acquired over 70 years of expertise in the design and manufacture of hydraulic and mechanical equipment with high demands to reliability during use in harsh offshore environments.

Imenco in Scotland has an extensive track record of providing acoustic communication systems for the offshore oil and gas industry.

“I’m pleased to see that knowledge sharing between two geographically separate parts of Imenco has resulted in the coming together of technologies, which can not only save the customer money in the short and long term, but also reduce the risk of environmental impact due to hydraulic leaks.” Andrew Connelly – Product Line Manager, Imenco

Feel free to contact Andrew Connelly, Product Line Manager – NASCoM to know more.

+44(0)1224 226568, andrew.connelly@imenco.com