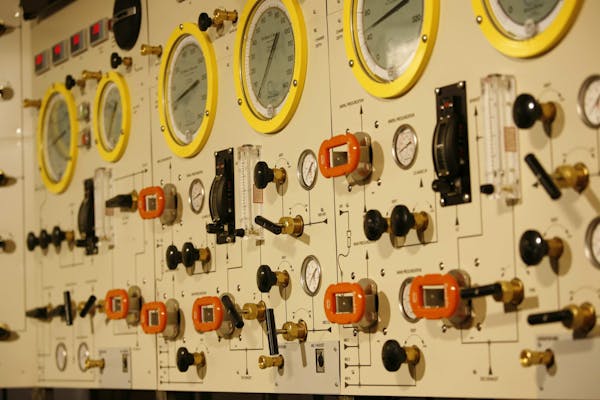

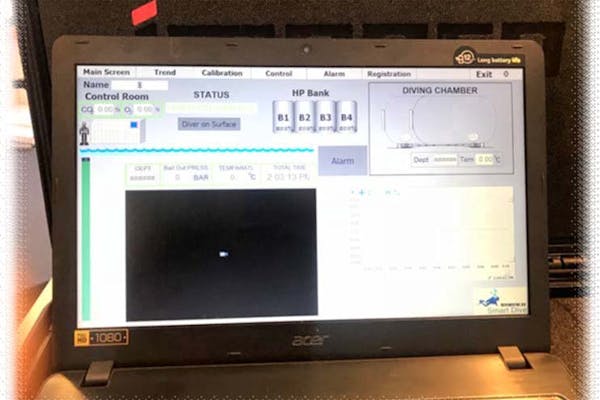

These electric Divers Hot Water Machine can be manufactured either with the very latest automated control systems (touch screens) or a more simplified, and cost effective manual version (push buttons)

The heaters are designed to a wide range power sources from 80 to 450 kW and can deliver up to 90 litre/min of hot sea water to the diver. In addition, the units can also be delivered as a mobile system.

For integration into an existing DSV’s – diving support vessels – Imenco can provide a complete turn- key operation, to include design, manufacture, testing, installation & commissioning of Divers Heater, Stand-By Volume Tanks for emergency use, Filtration System and high pressure hot sea water pipework and distribution system.

All of the Divers Hot Water Machine are DNV approved and capable of delivering 30 L/min per diver as specified in DNV RP-401 and NORSOK U-100.

Please read one of our customer feedbacks below: